The FutureDial Blog

(1.29.2024)

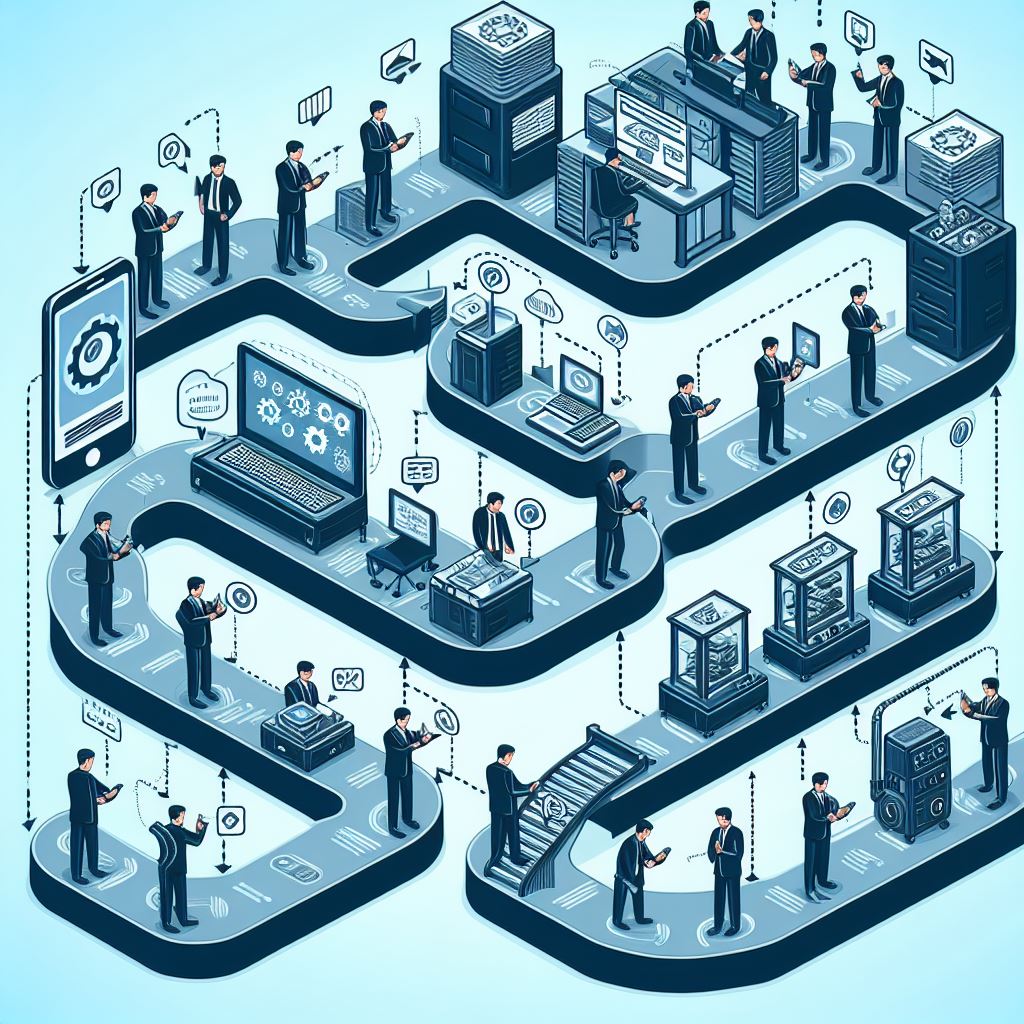

Notes from the Field: Best Practices for Embracing Change in Mobile Phone Refurbishment Operations

TAKEAWAY: Ready to dive into the world of mobile phone refurbishment success? This blog article summarizes some of our field observations of customers in the industry and mobile supply chain, on what it takes to make it big in the game. We’re talking about being savvy with change, being strategic with automating processes, picking business partners you can rely on for the long haul, and keeping things real with realistic operational expectations.

First things first, change is good: Embrace it like a pro to stay ahead in this dynamic mobile market. Our tip? Go for a phased automation rollout – assess your current ops, spot those golden opportunities, and scale up gradually for the win. And when it comes to business partners to help you improve your refurbishing operations, don’t just go for the cheapest option. Team up with the experienced, knowledgeable and reliable ones who are up for the long-term ride. It’s all about collaboration and customization.

Now, let’s talk about the real MVPs – your human workforce. Our observations out in the field summarize the inside scoop on setting them up for success. Clear instructions, top-notch training, automating mundane tasks for greater productivity, user-friendly interfaces – these are the secrets to their greatness. And keep those expectations real: we know humans have their limits, so find that sweet spot between efficiency and expertise.

In a nutshell, the winning formula? Reliable partners, realistic expectations, and a dash of radical adaptability. That’s your ticket to positioning your refurbishment business for growth, profitability, and customer satisfaction in a competitive and evolving industry.

Introduction

As a mobile phone refurbishment business hums along each day, processing thousands of preowned mobile phones to qualify them for later resale in secondary markets, the business must constantly evolve to stay competitive and meet customer demands.

Throughout our field observations, we have gleaned valuable insights that shed light on the critical factors that drive success in this dynamic industry. From embracing change strategically to optimizing automation deployment, choosing reliable partners, and setting up human operators for success, every aspect and touchpoint of the refurbishment process plays a vital role in achieving efficiency and profitability.

We will review a few of these observations, and highlight their significance in the pursuit of success for mobile phone refurbishing businesses.

1. Change as a Strategic Asset in Mobile Phone Refurbishment:

In the fast-paced reverse mobile supply chain, the ability to adapt and embrace change strategically is essential for businesses to thrive and succeed. Change is an inevitable part of any successful business, and mobile phone refurbishing centers are no exception. Businesses in mobile phone refurbishment need to see change not as a threat, but as a strategic tool for success. By embracing change thoughtfully and strategically, mobile device refurbishing businesses can not only tackle challenges effectively but also seize opportunities for growth, stay ahead of competitors, and enhance customer satisfaction. Let’s dig into why change is a strategic asset and how mobile device refurbishing centers can use it to ride the waves of market shifts, adopt and leverage new technologies, and optimize their operations for efficiency and growth.

Adapting to Market Shifts: The mobile phone refurbishment industry is dynamic and constantly evolving. Things move fast: market trends, customer preferences, and new tech can change on a dime, and it affects how you do business. Mobile device refurbishing centers that embrace change as a strategic asset can swiftly adapt to these shifts. They’re the ones who can roll with the punches. These centers keep their ears to the ground, figure out what customers are buzzing about, and tweak their refurbishment game to stay on trend. Being agile and proactive in responding to market changes positions refurbishing centers as leaders in the industry.

Leveraging New Technologies: New technologies constantly emerge, and in the refurbishment game, being buddies with change means being besties with innovation. Embracing change allows refurbishing centers to stay at the forefront of technological advancements and capitalize on new tools and methodologies that enhance operational efficiency, helping their processing operations run like a well-oiled machine. Think automation, artificial intelligence, machine learning, and data-driven analytics – these are just some examples of technologies that can optimize the refurbishment workflow and kick overall productivity up a notch.

Optimizing Operations for Efficiency and Growth: Let’s talk about making refurbishing operations not just good but great for top-notch efficiency and growth. Here’s the scoop – intelligently implemented changes can kick things into high gear. Refurbishing centers that have the “Change is Good” mindset are better equipped to take a good, hard look at how things run, figure out where the bottlenecks are, eliminate redundancies, and streamline workflows. This isn’t just about improving productivity to get things done faster – it’s about cost savings and increased profitability. And the secret sauce? A focus on continuous improvement ensures that the improvement vibes keep going strong throughout the business. That way, refurbishing centers remain innovative and forward-looking, positioning them as industry leaders.

Encouraging a Culture of Innovation: Embracing change as a strategic asset is not just about adopting new technologies or grabbing the latest gadgets; it’s also about fostering a culture of innovation, making change into a valuable teaching force for your business operation. Picture this: a workplace where everyone’s chatting, throwing ideas around, and being creative geniuses. That’s the vibe we’re talking about. Encouraging your workforce to share their thoughts, give feedback, and toss in their creative sparks creates a work environment where fresh ideas and improvement suggestions are welcomed. And here’s the bottom line: When employees feel like their ideas matter, they’re all in, and empowered to contribute to positive change. The workforce become more engaged, invested, and committed to the success of the refurbishing center.

Mitigating Risks and Uncertainties: Change naturally brings risks and uncertainties, but here’s what we have observed: if you play your cards right, those risks can turn into wins. Approaching change strategically allows refurbishing centers to anticipate challenges. Imagine this – conducting Sherlock-level risk assessments, spotting potential bottlenecks, and having Plan B contingency plans in place. By considering the long-term implications of change, businesses minimize risks and ensure a smooth transition during transformation.

Recognizing change as a strategic asset, not a villain, is the industry secret. It’s the key to riding market shifts, adopting the latest tech, running operations like a well-oiled machine, and turning the workplace into an idea hub. This thoughtful and strategic embrace transforms refurbishing centers into agile, innovative, and customer-centric powerhouses. Picture it: these centers don’t just roll with the punches; they masterfully handle any curveballs the market throws. As the industry evolves, centers embracing change as a strategic asset emerge as leaders. They deliver top-notch refurbished mobile devices to the market, consistently exceeding customer expectations and setting new standards for excellence.

2. Taking Automation Deployment One Step at a Time – A Phased and Scalable Approach:

2. Taking Automation Deployment One Step at a Time – A Phased and Scalable Approach:

No doubt, automation has done wonders for how things roll in mobile phone refurbishment. It’s like having a superhero on the processing line – efficient, accurate, and boosting overall productivity. However, going all-in on automation all at once can be a bit of a mountain climb, with risks and challenges in tow. So, how do you nail it without the stress? To ensure a successful and seamless integration of automation technologies, our observations have shown that refurbishing centers should embrace a phased and scalable approach to deployment. By breaking down the automation implementation into bite-sized manageable steps, refurbishing businesses can effectively address any hiccups or issues that may arise to tackle them head-on, optimize processes, and achieve the best possible results.

Assessing Current Operations: Before embarking on automation deployment, we have observed that refurbishing centers must do a little detective work first by conducting a thorough assessment of their current operations – let’s call it the operations check-up. Refurbishing centers need to take a good look at how things are rolling right now. This evaluation isn’t about finding flaws; it’s about spotting areas that could use a sprinkle of automation magic, and pinpoint potential bottlenecks or inefficiencies where things might be a bit wonky. Getting the lowdown on the specific needs and pain points sets the stage for a smart and strategic automation game plan. A targeted and strategic approach is like giving your operations a little boost in all the right places.

Identifying Key Automation Opportunities: Now that we’ve got the lowdown from our comprehensive assessment in hand, let’s pinpoint the sweet spots for automation – the real game-changers. Think repetitive tasks, data entry processes, quality control checks – or any other tasks that could use a dose of automation magic. We’re talking about those tasks that can be optimized, streamlined, and made way more efficient with some automation technologies. Prioritizing areas with high potential for improvement ensures that the initial phases of deployment yield significant benefits and a positive return on investment. It’s like choosing the spots where automation can flex its muscles and deliver big-time benefits from the get-go.

Implementing Pilot Projects: A phased approach to automation deployment often involves starting with pilot projects. We have observed that these projects involve implementing automation technologies in baby steps, in a controlled environment, such as a specific processing station or a subset of devices. By testing the automation systems on a smaller scale, it is like trying out new tech in a safe zone, maybe a specific processing spot or a group of devices, keeping it controlled and cozy. We have seen firsthand how testing the waters on a smaller scale lets refurbishing centers evaluate their effectiveness, spot any hiccups, gather valuable feedback from staff, and identify any potential challenges or areas for improvement. It’s like dipping your toes into the automation pool before doing a full-on cannonball-dive.

Learning and Adapting: So let’s spill the tea on pilot projects – they’re like sneak peeks into how automation interacts with existing processes and staff workflows. Taking notes and learning from these pilot adventures, refurbishing centers get to tweak the automation systems and adapt them to the unique requirements of their operations. It’s all about learning and adapting, making sure these tech wonders seamlessly fit like a glove into the refurbishment workflow. This back-and-forth ensures the automation becomes part of the refurbishment operation with zero hiccups.

Scaling Up Gradually: As refurbishing centers gain confidence and experience with automation, they can gradually scale up its deployment. Expanding automation to additional processing stations or incorporating it across various refurbishment tasks becomes more manageable, thanks to the insights gained from the pilot projects. A gradual and controlled scaling-up process minimizes disruptions and allows businesses to keep an eye on things, fixing any bumps in the road as they go.

Continuous Improvement: Automation deployment is not a one-time event but an ongoing journey of continuous improvement. Refurbishing centers should continuously monitor the performance of automation systems, gather feedback from staff, and and spotting areas for a optimizing tune-ups.

Embracing a culture of continuous improvement ensures that automation technologies remain aligned and in-sync with evolving business needs and contribute to long-term efficiency gains. We have observed that taking automation deployment one step at a time through a phased and scalable approach is the key to successful integration of automation technologies in mobile phone refurbishment centers. By thoroughly assessing current operations, identifying key automation opportunities, implementing pilot projects, and gradually scaling up, refurbishing centers can effectively leverage automation to enhance efficiency and accuracy.

Embrace the learning vibe from each phase, and you’ve got the golden ticket to unlock automation’s full potential. We have seen in the field how embracing continuous improvement enables businesses to unlock the full potential of automation and stay at the forefront of innovation in the mobile phone refurbishment industry. This strategic and measured approach isn’t just a plan; it’s the way to roll for sustained growth, improved productivity, and greater customer satisfaction.

3. Choosing Reliable Partners over Cheapest Vendors – Fostering a Strategic Automation Partnership:

The decision to make the big move to implement automation software and robotics in mobile phone refurbishment centers can be a game-changer, like flipping the switch for operational efficiency and overall profitability. However, here’s the deal: the success of automation deployment hinges on choosing the right partners to collaborate with. While cost considerations are undoubtedly important, refurbishing businesses must prioritize reliability and a partnership-driven approach when selecting automation solution providers. A true partnership goes beyond your average transactional vendor relationship, it’s about teaming up, collaborating, customizing – a true partnership and a shared commitment to achieving the goals of the refurbishment business. Let’s delve deeper into why choosing trustworthy business partners beats going for the cheapest vendors. It’s all about how a savvy automation partnership can lead to optimal results.

Understanding the Importance of Reliability: When it comes to automation deployment, reliability is a big deal. So, when refurbishing centers use automation tech, it’s all about making things smoother, accurate, and more productive. Having a reliable partner is key — they make sure the automation solutions are strong, efficient, and customized for the center’s specific needs. A reliable partner doesn’t just give you a great product; they also have your back with top-notch support to tackle any hiccups during and after implementation.

Aligning with Business Objectives: When teaming up with businesses and making automation work hand in hand with the processing center’s business goals, a reliable partner doesn’t just dive in; they take the time to get what makes the refurbishing center tick—knowing the challenges, goals, and unique needs. Working closely with the center’s crew, the automation solution provider can tweak the tech to blend right in with the existing flow and add to the overall success of the business.

Emphasizing Collaboration: A true partnership fosters a culture of collaboration and taps into the power of teamwork. A real partnership is all about creating a collaborative vibe between the automation solution provider and the refurbishing center. It’s not just about handing over a cool product; it’s an ongoing chat, sharing feedback, and always finding ways to do better. Regular talks and brainstorming sessions make sure that the automation setup stays on point, flexible, and in sync with whatever the center needs as it keeps growing.

Providing Customized Solutions: Ideally, you want to implement solutions that fit like a glove. Every refurbishing center has its distinct operations and processes, so picking a trusty automation partner is like choosing a buddy who gets it. Off-the-shelf automation might not cover all the quirks of the center. A reliable partner takes the time to develop tailor-made solutions that maximize efficiency and productivity.

Commitment to Long-Term Success: The real deal is in finding a reliable partner who’s in it for the long haul, namely, the long-term success of the refurbishing center. You want someone who’s not just there for the initial implementation phase, but is committed to seeing the refurbishing center thrive – we’re talking ongoing support, updates, and keeping things in tip-top shape. With tech moving at lightning speed, a reliable partner makes sure the automation solutions stay fresh and keep bringing value as the center grows and evolves.

Prioritizing Customer Success: You want to pick a partner who’s all about your success. When you choose a reliable partner, you’re going for a solution provider that prioritizes your business above all else. It’s not just a transaction; it’s a tag team working towards peak results for the refurbishing center. A trusty partner is all in, dedicated to helping you tackle challenges, fine-tune processes, and hit the top tier of operational awesomeness.

Selecting reliable partners over cheapest vendors is a strategic decision that can significantly impact the success of automation deployment in mobile phone refurbishment centers. Reliability, alignment with business objectives, collaboration, customized solutions, commitment to long-term success, and a focus on customer success are the hallmarks of a true partnership. When picking an automation partner, go with one who is genuinely invested in your success and goals. A smart partnership turbocharges refurbishing centers, unleashing the full power of automation for top-notch efficiency, accuracy, and your center’s competitiveness.

4. Setting Human Operators Up for Success:

4. Setting Human Operators Up for Success:

Let’s talk about the magic combo of humans and tech in mobile phone refurbishment. In the mobile phone refurbishment process, human operators play a vital role in ensuring the quality and accuracy of refurbished devices. Yes, automation can be awesome, but guess what? Humans are the real MVPs for nailing quality and accuracy in refurbished devices. They bring much of the attention to detail, and adaptability that machines might miss. To max out productivity and dodge errors, refurbishing businesses need to create a space where human operators can shine. By providing clear instructions, implementing training programs, and incorporating user-friendly interfaces that can automate the mundane tasks, businesses can provide the secret sauce for setting up their human workforce to rock their roles and foster a culture of excellence in the refurbishment process.

Clear and Concise Instructions: When setting human operators up for success, providing detailed guidelines for each task, along with step-by-step procedures, helps operators understand their responsibilities and perform tasks efficiently. Written procedures, visual aids, and digital work instructions can enhance clarity and reduce the chances of misunderstandings or mistakes.

Comprehensive Training Programs: Top-notch training is key for operators to shine. It’s not just about the tech stuff; we’re talking best practices, safety, and quality control. Keep the learning vibes going with ongoing training, refreshers, hands-on sessions, simulations, and practical experiences. That’s the recipe for boosting confidence and skills in their roles.

User-Friendly Interfaces and Tools: The tools and interfaces used by human operators significantly impact their efficiency and performance. Refurbishing businesses, listen up: invest in user-friendly, easy-to-navigate interfaces. Keep things smooth and reduce admin time so operators can dive into the good stuff. Oh, and throw in comfy workstations and tools that cut down on strain and fatigue – that’s the secret sauce for boosting comfort and productivity.

Empowering Decision-Making: Let’s talk about the power of human brainpower! Operators bring unique expertise and critical thinking that machines might miss. Refurbishing centers, give your operators the green light to make informed decisions within the rules. This boosts their sense of ownership and responsibility, and guess what? It encourages them to spot and report issues early, adding a dash of continuous improvement to the refurbishment process.

Continuous Improvement Initiatives: Operators thrive on regular constructive feedback and recognition. In refurbishing centers, open communication is the name of the game. Allow operators to spill the beans on insights, challenges, and ideas for making things better. And also recognizing and celebrating operators’ achievements and contributions creates a positive vibe and makes them proud of the awesome work they’re doing.

5. Realistic Expectations for Human Operators – Striking the Balance Between Efficiency and Expertise:

In the processing line operation, human operators are instrumental in maintaining accuracy and ensuring the quality of refurbished devices. But here’s the deal: expecting them to juggle too many tasks per device? Not cool. Refurbishing centers, let’s be realistic about human memory. Set achievable expectations for accuracy by simplifying processes and tossing in tools to help your operators shine. That’s the ticket to maxing out efficiency and rocking productivity with a touch of automation magic.

Understanding Cognitive Limitations: Human memory has limitations, and expecting operators to recall an overwhelming number of tasks for each device can lead to errors and inconsistencies. Set realistic expectations, and prioritize critical tasks and those that require human expertise, while automating repetitive and routine tasks whenever possible.

Simplifying Processes: Keep it simple for your operators. Refurbishing centers, streamline those processes. Less steps, fewer tasks for each device. Throw in clear instructions, visuals, and digital guides. No need to memorize – it’s all about consistent performance without the mental burden to remember everything.

Providing Tools and Automation Support: Let’s talk about giving your operators some superhero tools. Automation is the sidekick they need. Refurbishing centers, let automation handle the tedious, repetitive, boring stuff like data entry and routine inspections. In this way, automation frees up your human workforce to tackle the cool, complex stuff in refurbishment. Think barcode scanners, computer vision, and A.I. – these all help to boost accuracy, productivity, and give your operators a breather from cognitive overload.

6. Solutions that Work FOR You:

The efficiency of operations directly impacts a refurbishing business’s success. In refurbishing, nailing efficiency is the key to success. Centers, go for systems that blend smoothly with your operations, giving your staff the power to shine and supercharging overall productivity. Tailor solutions to your needs, streamline processes, and always be on the lookout for ways to level up. That’s how refurbishing centers turn up the dial on workflows, hitting top levels of productivity and making their customers happy.

Tailoring Solutions to Specific Needs: No two mobile phone refurbishing centers are identical, and each has its unique set of challenges and requirements. A one-size-fits-all approach to solutions and systems may not effectively address the specific needs of a center. Refurbishing centers should collaborate with automation solution providers to develop customized solutions that align precisely with their operations. By understanding the center’s workflows, pain points, and objectives, solution providers can tailor automation technologies to optimize efficiency and complement human operators’ expertise.

Streamlining Processes for Seamless Integration: Let’s talk about making things flow like magic. In refurbishing, the secret sauce is seamless integration. Centers, take a close look at your processes – figure out where automation can bring the wow. Think barcode scanning, A.I.-powered data analysis, and robotic helpers. You can integrate these strategically to swoop in for repetitive tasks, cut down on manual work, and crank up the accuracy. A tight-knit automation crew ensures that solutions work harmoniously with your staff, simplifying tasks and enhancing productivity.

Empowering Staff with User-Friendly Interfaces: User-friendly interfaces are crucial for optimizing human operator performance. Intuitive and easy-to-navigate interfaces reduce the learning curve for staff, enabling them to adapt quickly to new technologies and processes. Refurbishing centers should prioritize solutions that enhance user experience and simplify the execution of tasks.

Measuring Success through Data and Metrics: Data-driven insights are invaluable for measuring the success of implemented solutions. Refurbishing centers should leverage data and analytics to monitor key performance indicators (KPIs) and measure the impact of automation technologies on productivity, accuracy, and customer satisfaction. We have observed that data-driven decision-making enables centers to make informed adjustments, optimize processes further, and achieve greater operational efficiency.

Aligning with Future Growth Strategies: Solutions and systems should be future-proofed to align with the center’s growth strategies and technological advancements. As the refurbishment industry evolves, centers must choose solutions that are scalable and adaptable to changing needs. We have seen that solution providers who prioritize ongoing support and updates ensure that the center’s automation ecosystem remains relevant and effective over time.

The Winning Formula: Reliable Partners, Realistic Expectations, and Radical Adaptability in Mobile Phone Refurbishment

Let’s talk about the winning moves in phone refurbishment. Change is the name of the game – so embrace it. Pick reliable partners, go big on automation, support your human heroes, and set realistic goals. That’s the secret sauce for success. Refurbishing businesses, take note – we have observed over and over how recognizing these game-changers sets a refurbishing business up for growth and profits. In this fast-paced industry, adapting, optimizing, and innovating are the tickets to long-term success and happy customers. Commit to excellence, be ready to evolve, and watch your phone refurbishing business thrive in this ever-changing market.

Your Enablement Partner Helps Your Refurbishing Business Success

Your Enablement Partner Helps Your Refurbishing Business Success

Your business success in the fiercely competitive preowned mobile device refurbishing and reselling industry is our priority at FutureDial. We’re not just a partner; we’re your strategic ally, here to elevate your business above the competition.

Whether you’re a wireless carrier, wholesaler, refurbisher, 3PL, MNO/MVNO, trade-in provider, or any other part of the reverse mobile device supply chain, FutureDial has your back. Our cutting-edge technology is tailor-made to supercharge your operations.

Ready to harness the full potential of automation for your business? Contact us today at sales@futuredial.com and let’s take your refurbishing game to new heights.

© 2024 FutureDial Incorporated. All Rights Reserved.